Crude oil is first processed in a refinery by running it through an Atmospheric Distillation Unit, typically referred to as a Crude Unit, where the crude is split into basic products or cuts based upon particular boiling point ranges of the product.

Crude oil is first processed in a refinery by running it through an Atmospheric Distillation Unit, typically referred to as a Crude Unit, where the crude is split into basic products or cuts based upon particular boiling point ranges of the product.

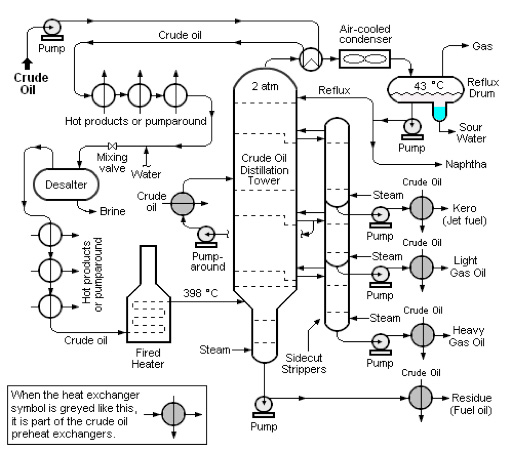

The crude oil is preheated by exchanging heat with some of the hot cuts from the atmospheric distillation column. Water is added and mixed with the crude to “desalt” or remove the inorganic salts, such as sodium chloride.

The desalted crude then proceeds through several more pre-heat exchangers, absorbing heat from the hot cuts off the atmospheric column once more. The crude oil is then routed to a heater where it is heated to a temperature of about 6500 to 7000F. At this temperature, the crude oil is a two-phase mixture of liquid and vapor. It now flows (transfers) to the bottom flash zone of the atmospheric tower.

Flash zone vapor rises up through the column, where it is contacted by condensing liquid flowing down due to gravity from the top trays of the column. At every stage, the liquid and vapor are in equilibrium. The highest boiling point liquid condenses on the tray just above the bottom flash zone, and the lowest boiling point liquid condenses at the top of the column.

Liquid fractions are drawn from the trays and removed based on their boiling point ranges. Light gases (methane, ethane, propane and butane) pass out the top of the column, while naphtha and straight run gasoline is formed in the top trays. Kerosene, diesel, and atmospheric gas oils are formed in the middle of the column, and residue or fuel oils exit at the bottom of the column.

After leaving the tower, all of the straight run distillates/product streams go to holding, intermediate storage tanks or downstream process units.

After leaving the tower, all of the straight run distillates/product streams go to holding, intermediate storage tanks or downstream process units.

|

Fraction |

Approx. Boiling |

Further Processing |

Final Products |

|---|---|---|---|

|

LPG |

-40 to 31 |

Sweetening | Propane |

|

Light Naphtha |

80 -185 | Hydrotreater | Gasoline |

|

Heavy Naphtha |

185 - 390 | Catalytic Reformer | Gasoline, aromatics |

| Kerosene | 340 - 515 | Hydrotreater | Jet fuel, No. 1 diesel |

|

Gas Oil |

350 - 650 | Hydrotreater | Heating Oil, No. 2 diesel |

Residue from the bottoms of the atmospheric crude column may be used as feedstock for cracking units, processed into lubricating oils and waxes, burned as fuel, or piped to a Vacuum Distillation Unit to recover additional heavy distillates.Click here to see a sampling of our project experience.